The entire series adopts high-efficiency servo motors, precision ball guide screw transmission, and is equipped with self-developed high-performance controllers and user-friendly operating software to ensure that every test is accurate and consistent, and meets ASTM, ISO, JIS, EN, GB, BS, CNS, etc. It complies with the standards of various countries around the world and is used for testing and research and development in related industries such as steel, non-ferrous metals, fasteners, rubber and plastics, textiles, paper, tapes, electronic parts and panels.

Universal material testing machine

Facebook

twitter

Email

product description

Features

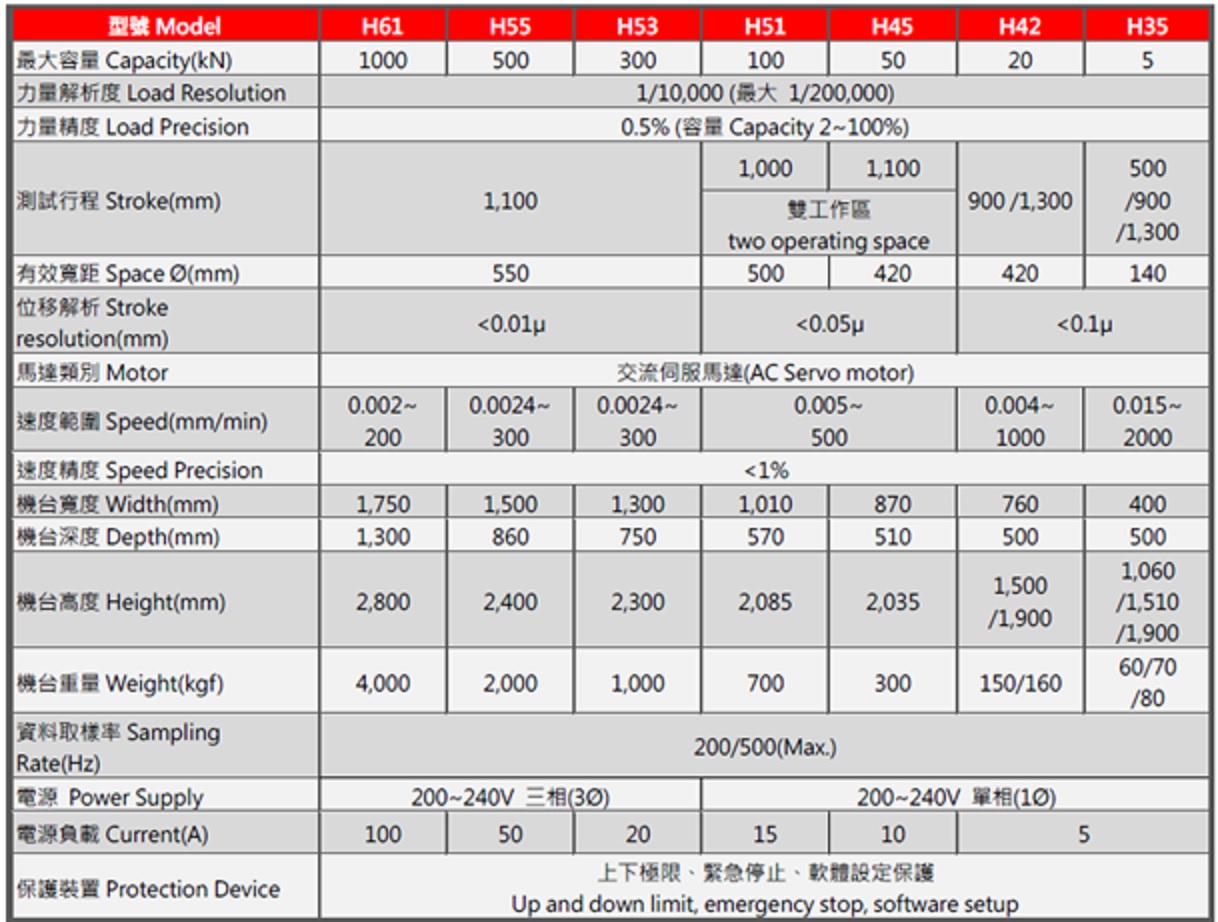

product specification

video introduction

Providing testing machines for various industries from small to medium power

High precision servo motor

The speed is accurately controlled, and multiple speed changes and stable rotation during testing can be performed as required.

*Traditional motors (knobs to adjust speed) or hydraulic systems, although cheap, have unstable speeds and poor movement and positioning accuracy.

The hydraulic system may also have problems such as oil leakage, heat generation, and noise. Subsequent maintenance and repair costs are high.

Precision Ball Lead Screw

High positioning accuracy, high rigidity, high stability, long life

load cell

YS-S series

10N~20 kN

*Capacity specified based on test sample

load cell

YS-L series

20kN~500kN

*Capacity specified based on test sample

Accuracy <1% (load capacity 5%~95%)

Resolution 1/10,000 (Max. 1/200,000)

The software includes a multi-stage calibration function for the sensor, with a larger measurement range and higher accuracy.

The factory calibration value is recorded in the chip inside the sensor, and there is no need to recalibrate when replacing it.