solution

Manual Measuring Instrument

5/5

The size measurement of various products is carried out in the form of image projection, which is suitable for all application fields for the purpose of three-dimensional coordinate measurement, and is widely used in various industries such as manufacturing and other industries.

Semi-automatic Measuring Instrument

5/5

The size measurement of various products is carried out in the form of image projection, which is suitable for all application fields for the purpose of three-dimensional coordinate measurement, and is widely used in various industries such as manufacturing and other industries.

Automatic Measuring Instrument

5/5

MIT Taiwan manufactures a fully automatic image measuring instrument, which can carry out program teaching and implement fully automatic measurement of the coordinate system. The combination of multi-segment lighting mode and fully electric lens magnification switching enables accurate measurement and is suitable for full inspection of mass production.

Large stroke measurement

5/5

Large stroke automatic image measuring instrument, image measuring instrument made in MIT Taiwan, precision grade granite mechanism, gantry three-axis mechanism, XYZ three-axis is driven by Panasonic servo motor.

High-precision automatic image measurement

5/5

High positioning accuracy model, combined with AOI search function, compensates XY displacement error, small Z-axis height measurement, suitable for IC solder ball and gold wire measurement, Z-axis repeatability ±0.5um (500X).

Customized Tool Microscope

5/5

The granite base stabilizes the fuselage, the XYZ line guide uses Japanese NB cross rollers, the Z axis has a thickness adjustment wheel, and is equipped with a Japanese Olympus objective lens, which can expand polarization and differential interference.

Industrial application

Measurement Application Software

Application software

Our company independently develops automatic image plus probe and laser displacement measurement application software, which can perform visual analysis, processing and detection of two-dimensional measurement coordinates, and can also use probes to measure three-dimensional geometric elements, or use Laser displacement measure flatness and height. Used in various precision manufacturing industries, such as: mobile phone components, molds, electronics, communications, machinery, hardware, plastics, instruments, clocks, PCB, LCD and other industries. Measurable materials include metal, plastic, rubber, glass, PCB, ceramics,,,, etc.

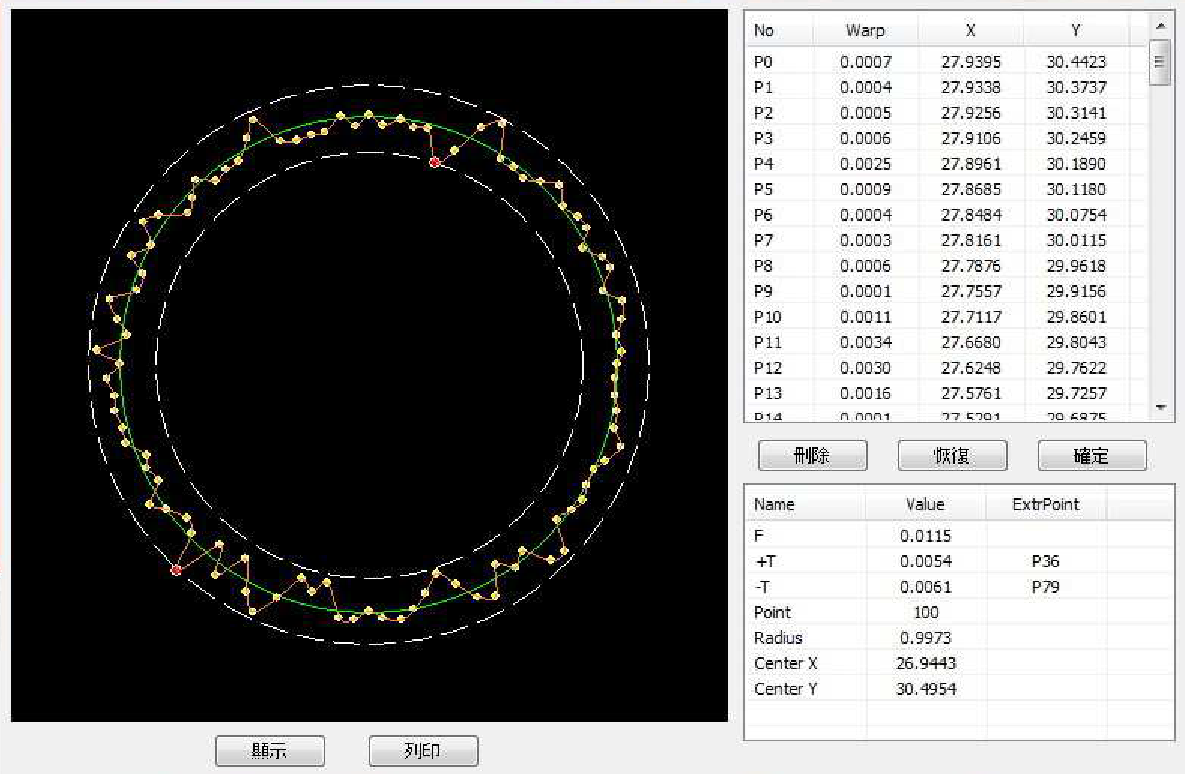

Geometric tolerance measurement

Geometric tolerance measurement

Measure the shape tolerance charts of straight lines, circles, planes, cylinders, and spheres. You can delete points with large errors in the measurement points as needed. You can print the shape tolerance charts of elements and view the shape tolerance properties.

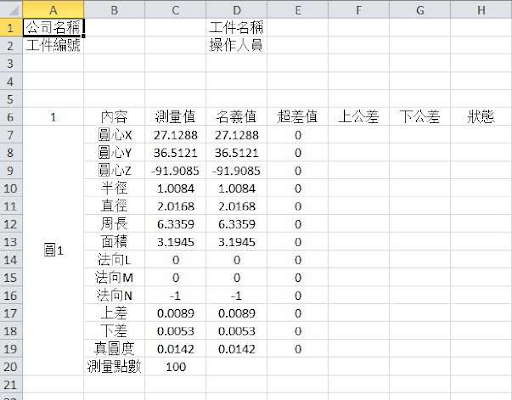

Form export

Multiple report export formats

You can set the content of element export, export direction, and whether to export bitmap, data report export, multiple built-in report types can be selected, and the form of report export can be customized.

It is mainly used for XYZ three-axis dimension measurement, and measures the dimensions of each workpiece in a non-contact manner.

Manual is XYZ three-axis manual movement, semi-automatic is Z-axis automatic movement, XY-axis manual movement, and automatic is three-axis automatic movement, including light source and lens magnification.

The stages are equipped with optical scales. According to the size of the workpiece to be measured, select the applicable XY stage for dimension measurement.

It can measure the geometric shape and shape and position tolerance for the size, and measure the shape profile by means of automatic edge finding, multi-segment point collection, and mouse point collection

Yes, our software interface has a drawing area, which can convert the elements measured by the edge detection of the workpiece into CAD file output, and can also be purchased to install a touch probe to measure and draw a 3D drawing.

Yes, all the image measuring instruments of our company are equipped with optical scales, which can establish the mechanical coordinate system and the workpiece coordinate system, realize the coordinate transformation of each coordinate system, and easily realize the conversion between the rectangular coordinate system and the polar coordinate system. Mutual conversion can realize the storage and use of each workpiece coordinate system.

Yes, our measurement software has a report export function, which can export WORD or EXCEL files. In addition, EXCEL files have five report formats to choose from, and data, graphics and photos can also be exported together.