Thick and heavy body can handle environmental vibrations

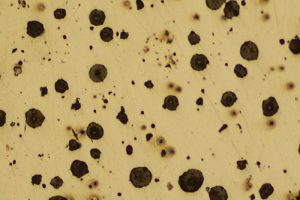

And can smoothly obtain clear images

There is no limit on sample height, and test pieces can be cut instantly for observation.

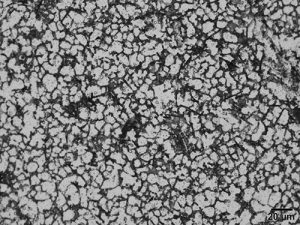

Inverted observation method solves the problem of uneven grinding

Thick and heavy body can handle environmental vibrations

And can smoothly obtain clear images

There is no limit on sample height, and test pieces can be cut instantly for observation.

Inverted observation method solves the problem of uneven grinding

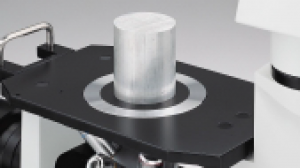

Paired with the original OLYMPUS original stage,Differences from upright metallographic microscopes

Inverted metallographic microscopes have no limit on sample height.No need to worry about loading and unloading issues.

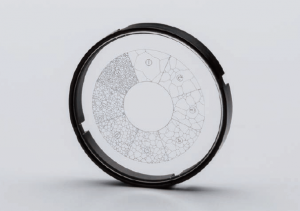

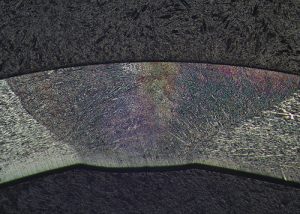

Observation and comparison of glass scratches

A variety of metallographic scribes can be added for comparison.Such as GRAIN SIZE grain number comparison.

The specifications of the scribing sheet are in accordance with ASTM E112, JIS G0551, ISO634

stage observation mirror

Installed between the stage and objective lens, it makes it easier toAdjust the observation purpose and target magnification.

Also helps prevent collisions between target and sample.

| Body model | GX53 | |

| optical system | UIS2 infinity optical correction | |

| Microscope body | light path | Reflected light/transmitted light (optional) |

| illumination | LED light source or halogen light source (optional) | |

| Z focal length | Adjustment stroke: 9 mm One circle of micro movement: 0.1mm Minimum micro movement: 1 μm |

|

| nose chakra | Electric OR manual | |

| Observation field of view | Wide angle FN 22mm | Reverse: three-eye observation Forward: three-eye observation |

| Stage | XY stroke 50X50mm | |

| weight | 28kg | |